The Ink lab includes state-of-the-art printing (inkjet, gravure, flexo, screen, 3D) and coating (spray, blade) techniques as well as equipment for advanced ink characterization.

For access to the lab, or for any general training, please contact the lab leader Dr Boyang Mao and Dr Vaishakh Kedambaimoole, or their deputy . For training on any of the equipment, please contact the Principal User or their deputy for the listed equipment.

While there is a range of devices in the Ink Laboratory, several of them require booking before use. The booking system can be found here.

Tensile Testing System - INSTRON

Principal User: DR Vaishakh Kedambaimoole The tool is used for the testing tensile strength of composite R&D components manufactured within CGC Facilities.

|

|

Twin-Screw Extruder - Composite Materials Model: Bandera Twin-Screw

The tool is used for the extrusion of polymer-composite materials

Users in Charge: Leader: Dr Goutam Prasanna Kar

|

NETZSCH LFA 467 HyperFlash® – Light Flash Apparatus

Principal User: Dr Goutam Prasanna Kar

New Dimensions in the Measurement of Thermal Diffusivity and Conductivity – Fast, Simple, Economical Sample throughput up to 4 times higher due to sample holder for 16 samples |

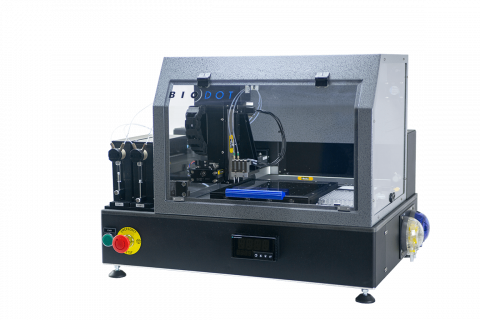

BioDot AD1520 Aspirate/Dispense Platform

Principal User: Dr Boyang Mao

The AD1520 is a tabletop workstation designed for high speed aspirating and dispensing applications to glass slides, microtiter plates or membranes. It has a compact footprint and can be configured with up to four dispensers, making it ideal for a research laboratory to investigate new applications. Chemical and biological reagents can be dispensed using the proprietary BioJet Elite technology. This technology couples the XYZ motion control system with the high precision displacement capabilities of a syringe pump and the high-speed actuation of a micro-solenoid valve. The three components synchronized together result in precise, non-contact liquid handling system. |

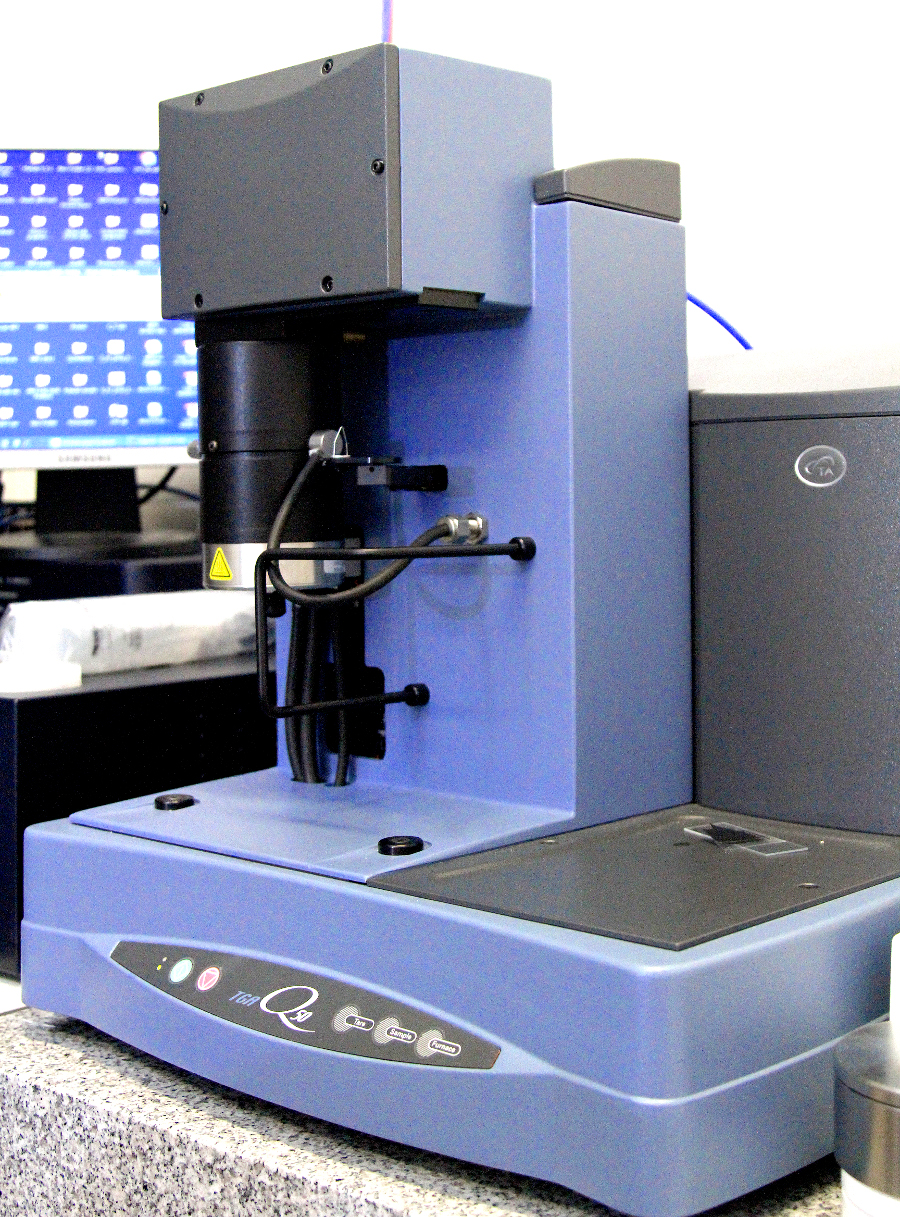

Discovery Hybrid Rheometer HR-1

Principal User: Dr Vaishakh Kedambaimoole

The Discovery Hybrid Rheometer is a rotational rheometer which uses the parallel plate method to measure the viscosity and viscoelastic properties of liquids or soft solids. It combines a patented advanced drag cup motor, a second generation magnetic bearing, force rebalance transducer (FRT), and the new patent-pending True Position Sensor (TPS) in a single-head Hybrid rheometer. The DHR has unprecedented performance specification and delivers unsurpassed direct strain control, direct stress control, and normal force measurement accuracy. The DHR features all popular TA innovations including patented Smart SwapTM geometries and the widest range of Smart Swap temperature systems and accessories commercially available. The result is the most advanced, versatile rheometer platform imaginable. The HR-1 is a rugged, accurate, field-proven rheometer. The HR-1 shares the cutting-edge technology of the Discovery Hybrid Rheometer family in a platform that is ideal for production control, asphalt manufacture, and a wide range of general measurements of viscosity and viscoelasticity

|

Testacolor 171

Principal User: Dr Boyang Mao

The testacolor 171 is an advanced printing system which enables the accurate single and multilayer printing of functional inks on flexible substrates. It includes exchangeable modules for gravure, flexo, screen printing. Advanced printing/coating system enabling accurate single and multilayer printing/coating of functional inks on flexible substrates. Designed to explore various possibilities and combinations of coating and printing with a precision of <20 µm in one machine. Easily and rapid exchangeable modules. Optical alignment system (optional). Measuring software, low ink consumption, 2 ml is sufficient for reproducible print (gravure/flexo). Customized printing forms. Chambered and open doctor blades. |

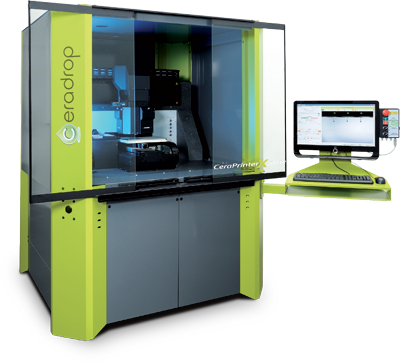

Ceradrop Super-Inkjet Printer X-Serie

Principal User: DR Vaishakh Kedambaimoole

CeraPrinter X-Serie is a TurnKey Materials Deposition Inkjet tool for process development in Printed Electronics and Smart 3D Printing. Thanks to its patented rotative head-holder “plug and play”, full curing area, in-situ characterisation devices and exclusive software suite, CeraPrinter X-Serie is a perfect “all inclusive” tool to enable advanced inkjet process development. Substrate up to 305 mm x 305 mm with thickness up to 10mm |

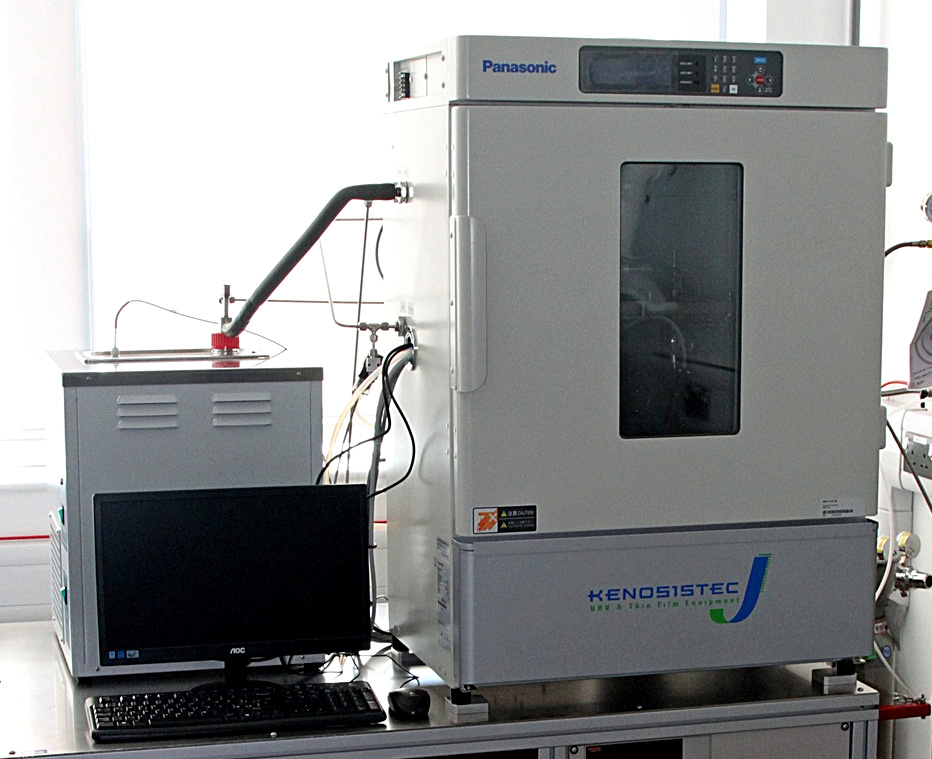

Climatic Chamber

Principal User: DR Vaishakh Kedambaimoole

Reproducible temperature and climate tests can be performed directly at your workplace. This is possible with the WTL and WKL chambers of Weiss. This series was specifically developed for use in laboratories. Compact dimensions – considerable intrinsic values.

|

CMP

Principal User: Chao Wen

Logitech’s CMP system offers nanometer level metarial removal capabilities on either individual die or wafers up to 100mm diameter.

|

Contact angle

Principal User: Dr Boyang Mao |

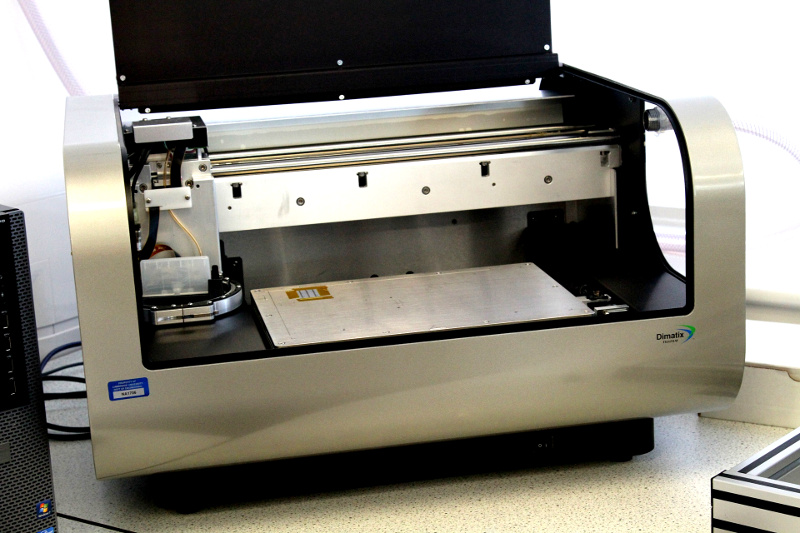

Dimatix inkjet printer

Principal User:DR Vaishakh Kedambaimoole The DMP-2850 allows the deposition of fluidic materials on an 8x11 inch or A4 substrate, utilizing a disposable piezo inkjet cartridge. This printer can create and define patterns over an area of about 200 x 300 mm and handle substrates up to 25 mm thick with an adjustable Z height. The temperature of the vacuum platen, which secures the substrate in place, can be adjusted up to 60°C. The DMP-2850 offers a variety of patterns using a pattern editor program. Additionally, a waveform editor and a drop-watch camera system allows manipulation of the electronic pulses to the piezo jetting device for optimization of the drop characteristics as it is ejected from the nozzle. This system enables easy printing of structures and samples for process verification and prototype creation.

|

Flexo printerPrincipal User: Dr Vaishakh Kedambaimoole |

Gas characterization systemPrincipal User: Dr Vaishakh Kedambaimoole The system provides:

With these parameters , the control program provides complete automatic sequences to verify all test in conformity with CEI norms. Computer Controlled Mass Spectrometer: Complete feedback on gas concentration is obtained by a computer-controlled mass spectrometer. Software PPT430 allows constant monitoring of cell contents, showing actual system concentration of gas. It is also possible to log data on disk, filling in reports on system activity. A special Close Source allows good readings even at low concentrations (a few PPM) of gas mixture (like CO, CH4, C4H10, and so on).

|

Inkjet 3D printer - Project 3500Principal User: Dr Vaishakh Kedambaimoole

|

Nikon large sample microscopePrincipal User: Dr Boyang Mao |

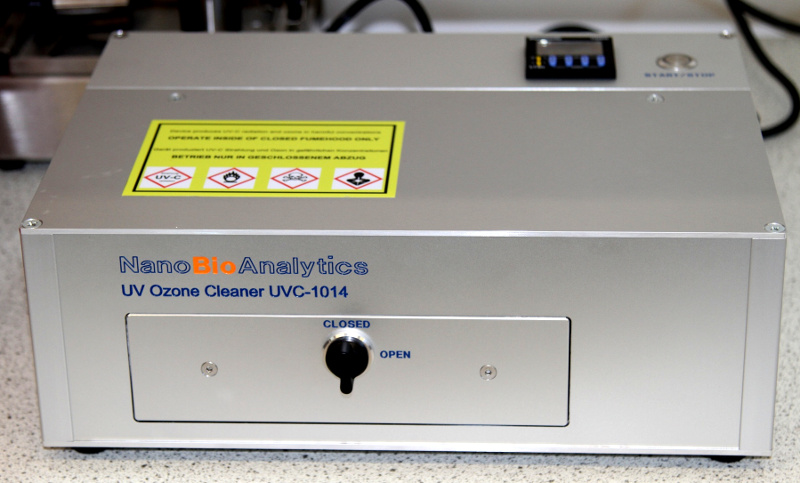

Ozone CleanerPrincipal User: Dr Vaishakh Kedambaimoole |

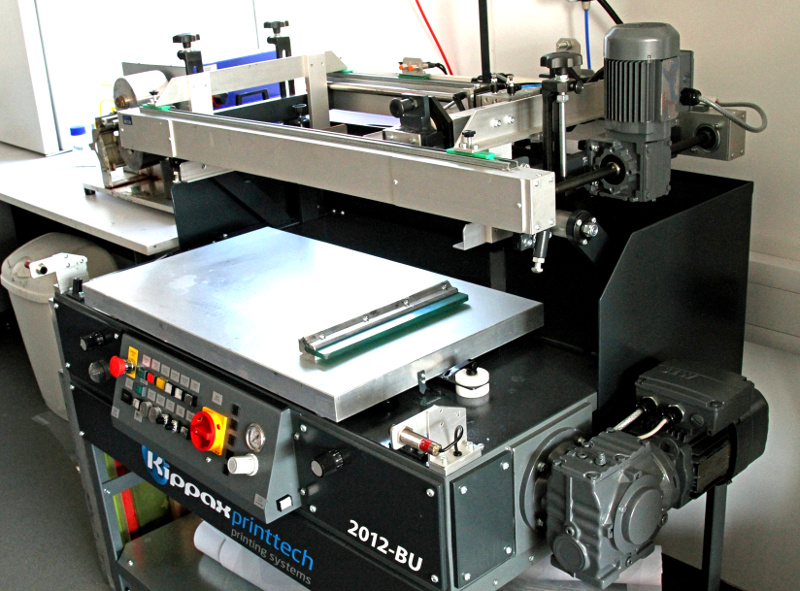

Screen printerPrincipal User: Dr Boyang Mao |

SCS spray coaterPrincipal User: DR Vaishakh Kedambaimoole |

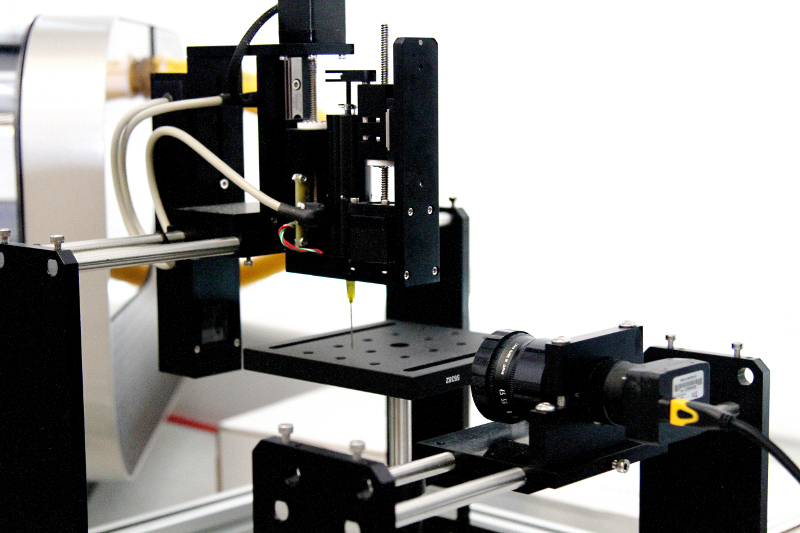

Sonoplotter - GIX MicroplotterPrincipal User: Dr Vaishakh Kedambaimoole |

Thermogravimetric Analyzer (TGA)Principal User: Dr Vaishakh Kedambaimoole This instrument is basically a sophisticated ash content test and is useful in measuring the inorganic filler content of plastics. TGA analysis continuously weighs a sample to the nearest millionth of a gram as it is heated to temperatures of up to 1000°C. As the temperature is increased, various components of the sample burn off and the weight percentage of each can be measured. Results are in the form of a graph with temperature plotted on the X-Axis and weight percentage plotted on the Y-Axis. A typical TGA scan looks similar to a staircase with each step representing a different compound. Our typical run is to ramp at 10°C per minute to 700°C in nitrogen followed by 10°C per minute to 900°C in air. Highly volatile matter is the material that burns off in nitrogen between ambient and 150°C. Medium volatile matter is the material that burns off in nitrogen between 150°C and 700°C. Combustible matter is the material that burns off in air but not in nitrogen at 700°C. Ash content is the material left at 900°C in air |

DSC Q20

|

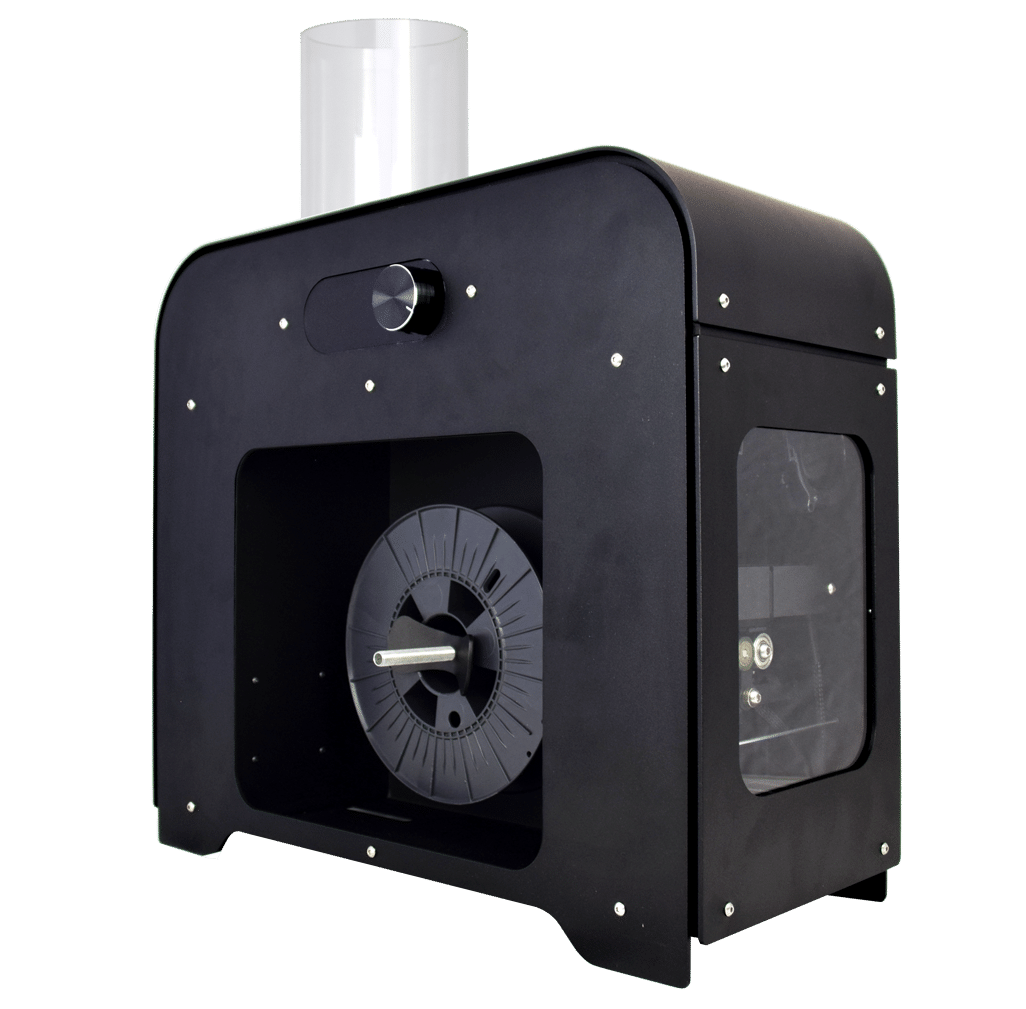

HS ExtruderModel: 3Devo 450 Composer

Single screw extruder with a high shear mixing element for monofilament extrusion of filled composites. Filament diameter is maintained by PID controller. Barrel temperatures up to 450 Celsius are possible.

Users in Charge: Leader:Dr Wing Chung Liuv

|

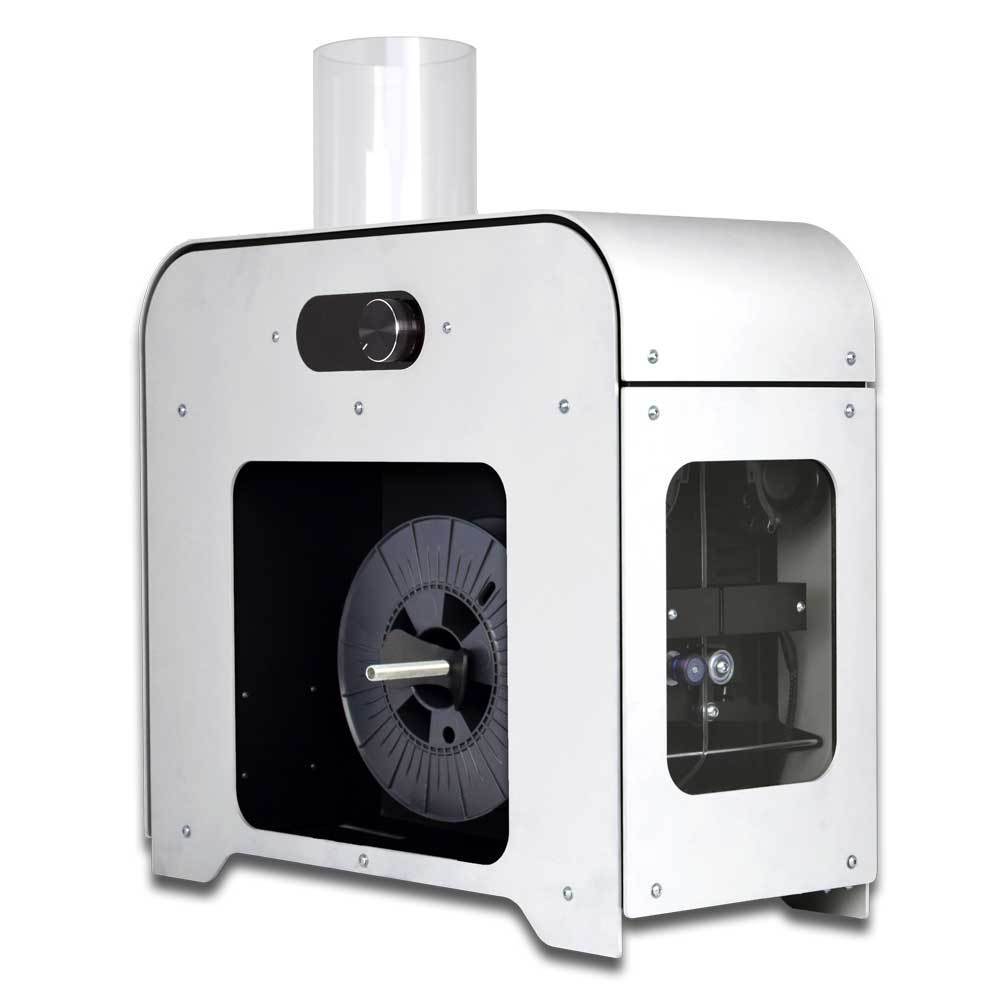

LS ExtruderModel: 3Devo 450 Precision

Single screw extruder with low shear and uniform heating for monofilament extrusion. Filament diameter is maintained by PID controller. Barrel temperatures up to 450 Celsius are possible.

Users in Charge: Leader: Dr Wing Chung Liu

|

DMA 850 Dynamic Mechanical AnalyzerModel: Discovery 850 The TA Instrument DMA850 is an advanced Dynamic Mechanical Analyser which is capable of characterising the viscoelastic properties of polymers such as the Storage and Loss Modulus and their dependence on temperature, frequency and magnitude of the applied forces. This allows deep insights to be obtained for polymer mechanical properties which gives a good assessment for their suitability in different applications. The DMA850 can achieve ultrahigh measurement sensitivity due to the extremely low forces (~0.1N) and displacements (~5 nm) that can be applied to the sample material. In addition, it is equipped with an additional liquid nitrogen Gas Cooling Accessory which extends the full operation temperature range to between -150 °C and 600 °C. The DMA 850 also comes with various types of sample holders which can be used to test the samples' response properties to different stresses such as tensile, compression or shear, making it a highly versatile equipment.

Users in Charge: Leader: Dr Wing Chung Liu

|

|

Bar Coater Table Principal User: Dr Vaishakh Kedambaimoole descriptionxxxxxxx |

|

Molder - Colin Project Model: Lab Line Platen Press P200SPrincipal User: Dr Vaishakh Kedambaimoole descriptionxxxxxxx |

|

Vacuum Oven Principal User: Dr Vaishakh Kedambaimoole descriptionxxxxxxx |

Ultimaker 3D printerPrincipal User: Dr Vaishakh Kedambaimoole descriptionxxxxxxx |

When in the Ink laboratory, please follow the local rules, downloadable here.