Below, you can find the list of equipment available in Class 1000 Cleanroom. A few are already available for use, others are being installed and will become available later.

Please use the booking system to use the equipment.

Plasma-Enhanced Chemical Vapour Deposition system (PE-CVD)Model: Vision 310, Advanced Vacuum AB

The plasma-enhanced chemical vapour deposition system is used for depositing amorphous Si, SiO2 and Si3N4.

Users in Charge: Leader: Mr Hao Chen Technical support: Lee Robinson

|

Reactive Ion Etcher (RIE-AV)Model: Vision 320, Advanced Vacuum AB

Used for reactive-ion etching of Si, SiO2 and Si3N4.

Users in Charge: Leader: Chao Wen

|

|

Inductively-Coupled Reactive Ion Etcher (RIE-ICP-AV) Model: APEX SLR, Advanced Vacuum AB

A load-locked system for inductively-coupled reactive-ion etching of Si, SiO2 and Si3N4 with an enhanced rate and anisotropicity.

Users in Charge: Deputy: Dr Dharmaraj Periyanagounder

|

|

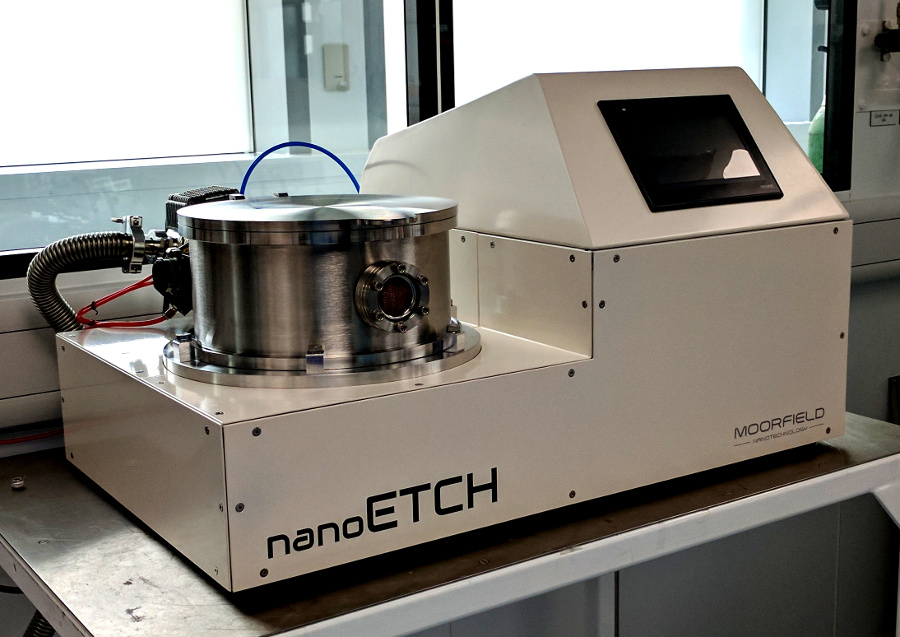

Reactive Ion Etcher (RIE-Nano) Model: NanoEtch, Moorfield Nanotechnology Ltd

The tool implements a unique soft-etching technology and provides the fine etching control crucial for graphene and 2D materials research in a convenient, benchtop package.

Users in Charge: Leader: : Dr Dharmaraj Periyanagounder Deputy : Lu Chen

|

|

Sputter-Coater (Spuco) Model: NanoPVD, Moorfield Nanotechnology Ltd

Moorfield NanoPVD is used for sputter-coating various metals and dielectrics. x1 DC + 2x RF sources, magnet pack, 2" targets, up to 4" wafers, no heating. Materials: Au, Ni, Cr, SiO2. Others are available upon request. Gases connected: O2, Ar, N2

Users in Charge: Leader: Sohail Abbas Deputy: Dr Yang Li

|

|

Plasma Cleaner (RIE-Femto) Model: Femto, Diener Electronics GmbH

This is a low-pressure plasma system used for plasma cleaning of substrates and activating surfaces. Gases connected: O2, N2

Users in Charge: Leader: Dr Dharmaraj Periyanagounder Deputy: Sohail Abbas

|

|

Electron-beam Evaporator (Evap-LEV) Model: PVD 200 Pro, Kurt J. Lesker

This PVD tool is used for e-beam evaporation of metals and dielectrics.

Users in Charge: Main: Dr Yang Li Deputy: Dr Hamideh Ramezani

|

|

Electron-beam Evaporator (Evap-IndEV) Model: Nexdep, Angstrom Engineering

This PVD tool is used for low-melting point metals as well as general materials for contacts' deposition.

Users in Charge: Leader: Dr Yan Wang Deputy:Dr Dharmaraj Periyanagounder

|

|

Thermal Evaporator (Evap-TEV) Model: MiniLab 60, Moorfield Nanotechnology Ltd

Manual and Automatic process modes, HMI, used for a thermal evaporation of selected metals.

Users in Charge: Leader: Dr Dharmaraj Periyanagounder

|

Plasma-Enhanced Atomic Layer Deposition (PE-ALD)Model: Fiji, Veeco

Used for Plasma-Enhanced Atomic Layer Deposition of Al2O3, TiO2, HfO2

Users in Charge: Deputy: Lu Chen

|

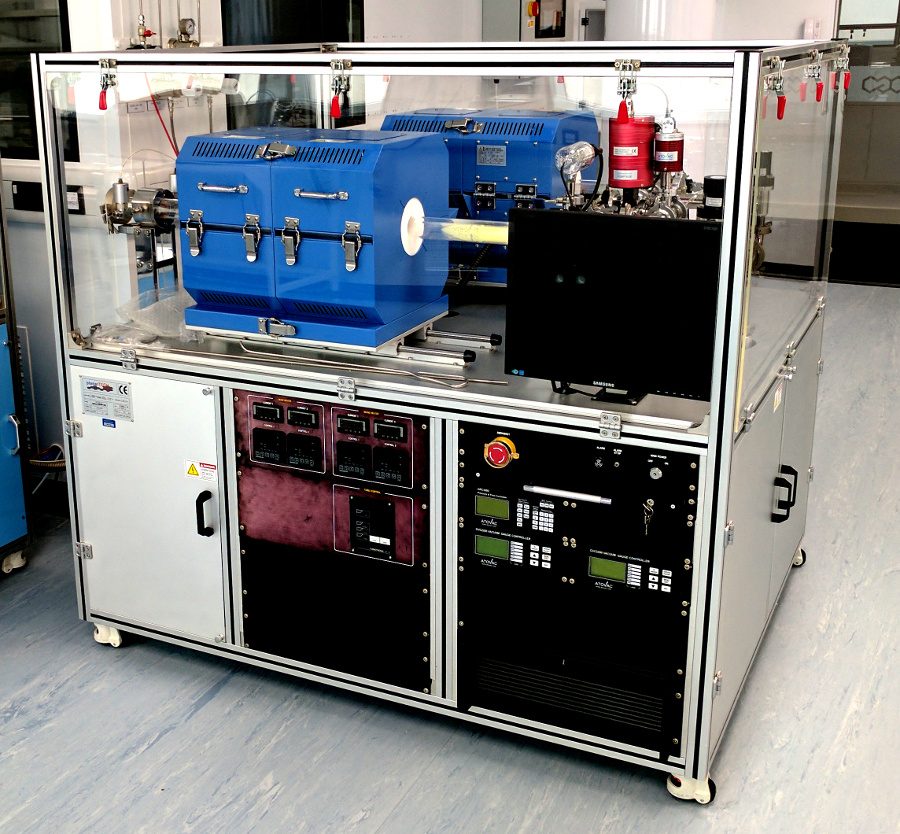

Ar-filled Glovebox (Evap-GB + Robot-GB)Model: M-Braun

Inert-atmosphere (Ar) glovebox with a robotized 3D graphene transfer system and a thermal evaporator. The thermal evaporator can be accessed from the inside as well as outside of the glovebox. There is a spinner and a hotplate inside.

Users in Charge: Leader: Mr Hao Chen Deputy: Dr Yang Li

|

Graphene Chemical Vapour Deposition (CVD-G)Model: Graphene Square

This chemical vapor deposition system is used to produce graphene films.

Users in Charge: Leader: Dr Dharmaraj Periyanagounder

|

|

Transition-Metal Dichalcogenides Chemical Vapour Deposition (CVD-TMD) Model: PlanarGROW-2S

A Dual-Furnace Chemical Vapour Deposition system for growth of 2D transition-metal dichalcogenides (WS, WSe2).

Users in Charge: Leader: Dr Dharmaraj Periyanagounder Deputy: Lu Chen

|

|

Plasma-Enhanced Chemical Vapour Deposition - Graphene (PE-CVD-G) Model: PlanarGROW-4S

Plasma-Enhanced Chemical Vapour Deposition system for growth of high-quality graphene.

Users in Charge: Leader: Hao Chen Deputy: Dr Dharmaraj Periyanagounder

|

Boron-Nitride Chemical Vapour Deposition (CVD-hBN)Model: Planartechh-BN Chemical Vapour Deposition system for growth of Boron Nitride film

Users in Charge: Leader: Dr Dharmaraj Periyanagounder Deputy: Lu Chen

|

|

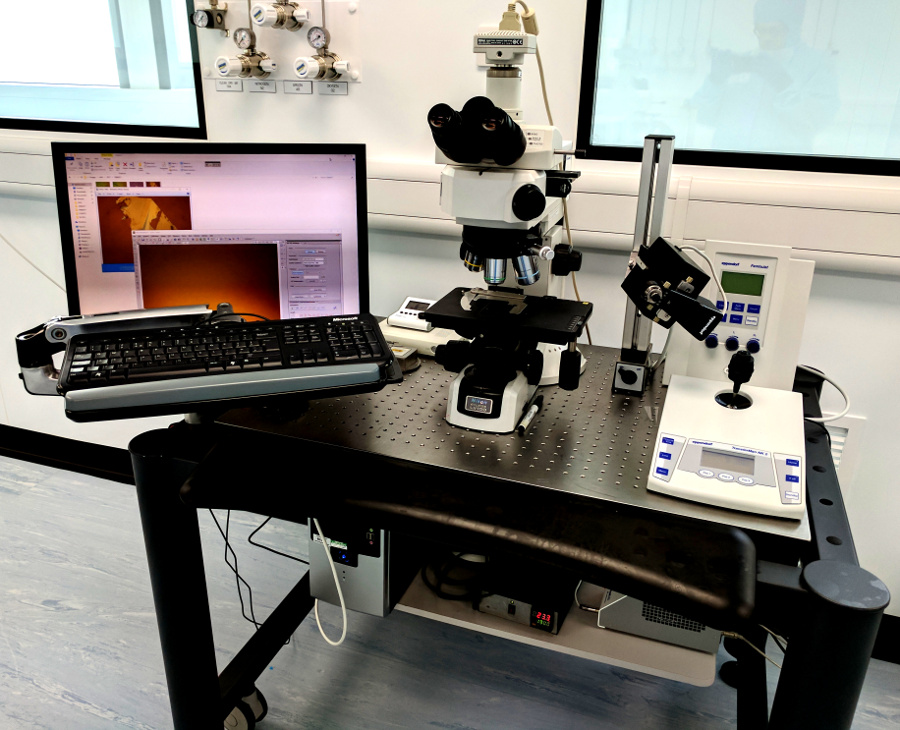

Transfer System x2 Model: Nikon Eclipse LV200 The tool is equipped with micro-manipulators and is based on Nikon Eclipse microscope

Users in Charge: Leader: Mr Hao Chen Deputy: Chao Wen

|

|

Furnace Tube – Ar/H2, N2/H2 Model: GTF-1200X

Tube furnace for the annealing processes up to 1100C in the 95% Argon/ 5% Hydrogen atmosphere.

Furnace Tube – O2 Annealing Model: GTF-1200X

Tube furnace for the annealing processes up to 1100C in the Forming Gas atmosphere.

Users in Charge: Leader: Dr Dharmaraj Periyanagounder

|

|

Acid Bench

This acid wet bench is used for graphene transfer, cleaning, and a number of other processes involving acids

Users in Charge: Leader: Dr Dharmaraj Periyanagounder

|

|

Solvent Bench This solvent bench is used for cleaning, preparation of samples for deposition, etching, as well as any other operations requiring solvents.

Users in Charge: Leader: Dr Dharmaraj Periyanagounder

|

Vaccum OvenModel: xxxxxx

descriptionxxxxxxx

Users in Charge: Leader: xxxxx

|

Aixtron CCS2D MOCVD (Awaiting commission)Model: CCS2D 19X2''

descriptionxxxxxxx

Users in Charge: Leader: Dr Dharmaraj Periyanagounder

|