Below, you can find the list of equipment available in Class 100 Cleanroom. A few are already available for use, others are being installed and will become available later.

Please use the booking system to use the equipment.

Electron-Beam Lithography (Royce EBL Suite) Model: EBPG 5200, Raith GMBH A state-of-the-art high-resolution/throughput Electron-Beam Lithography system capable of exposing 8-inch wafers. Users in charge: Mr Jonathan Griffiths |

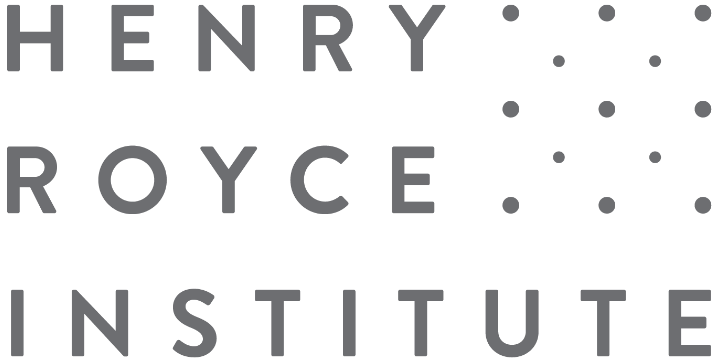

Laser WriterPrincipal User: Dr Hamideh Ramezani Model: LW-405B+, Microtech Srl

Used for the direct-write contactless optical lithography. Available wavelengths: 385 and 405nm. Best resolution (linewidth) is 0.6micron.

|

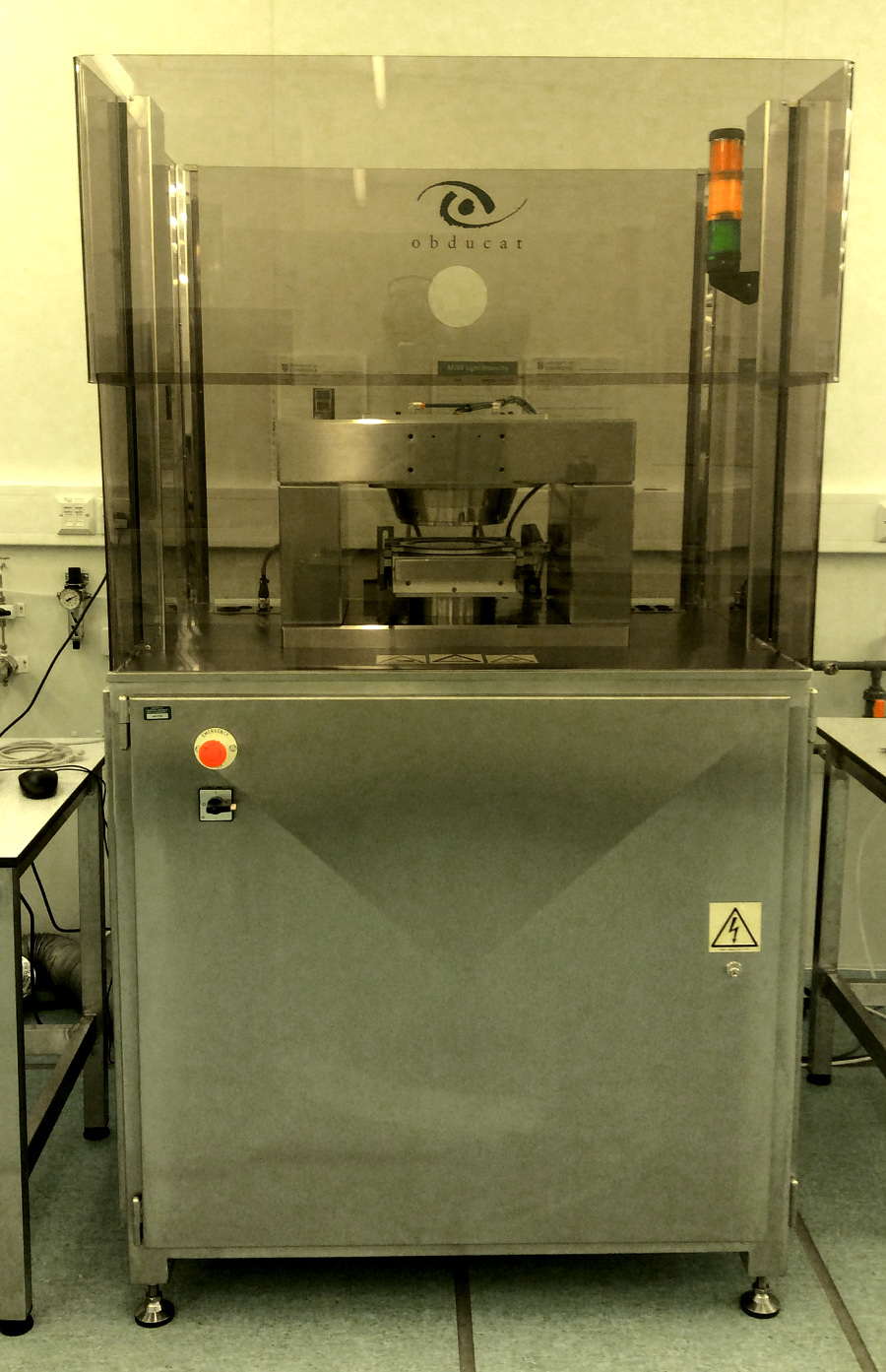

NanoimprinterDeputy User:

Model: Obducat Eitre 6 with UV curing option. The tool is used for high resolution nanoimprinting.

|

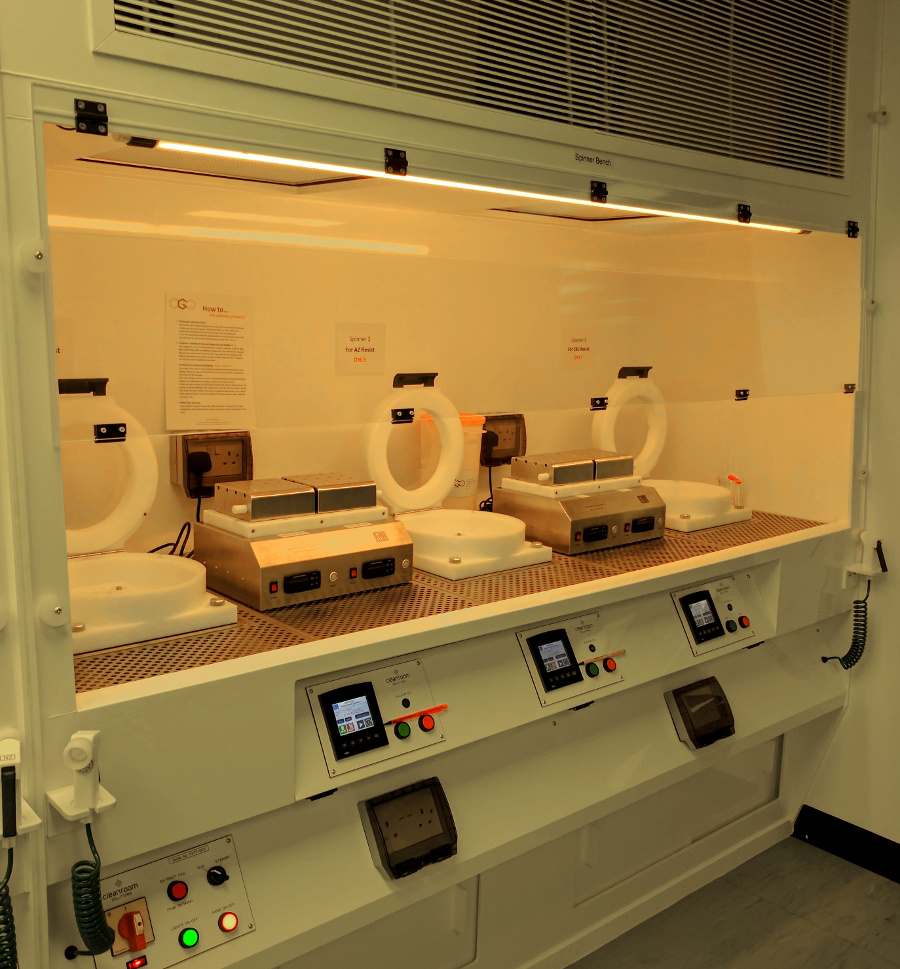

Resist Preparation wetbenchThe wetbench is equipped with three spinners and four precision hotplates from EMS.

Processes available: - SU-8 negative photo-resists - AZ/LOR positive and negative photo-resists - PMMA/ZEP e-beam resists

Principal User: Dr Dharmaraj Periyanagounder Deputy User: Lu Chen |

Development and Cleaning wetbenchThis wetbench is used for preparation of samples for lithography, as well post-processing (development, etc.)

Principal User: Dr Dharmaraj Periyanagounder Deputy User: Lu Chen |

|

Acid WetBench

Leader: Dr Dharmaraj Periyanagounder Deputy: Lu Chen

|

Triple FurnacePrincipal User:Chao Wen Deputy User:Dr Dharmaraj Periyanagounder The tool is used for deep oxidation of Si

|

Park AFM NX20Principal User: Dr. Yang Li Deputy User: Mr. Sohail Abbas AFM Mode:

The Park AFM NX20 is a high-resolution atomic force microscope (AFM) designed for precise nanoscale imaging and analysis. It features advanced non-contact mode technology, automated operation, and low-noise performance, making it ideal for materials science, nanotechnology, and life sciences research. Sample Size: Up to 200 mm (8 inches)

|

SUSS Mask and Bond Aligner MA/BA8 GEN4 (not bookable yet)Principal User: TBD Deputy User: TBD The MA/BA Gen4 MA/BA8 delivers exceptional process results through its advanced automation. Features such as constant dose mode, an automated exposure time control unit, and auto-alignment optimise process parameters for enhanced precision. Equipped with the high-performance MO Exposure Optics system, it ensures ideal exposure conditions for superior outcomes. Additionally, its sophisticated mechanical design enhances adjustment accuracy, with a specially engineered top- and bottom-side microscope unit (TSA and BSA) that minimises TSA microscope travel and reduces vibrations for improved stability. Our system is equipped with the TSA option. Wafer size: 1'', 2'', 6'', 8''

|

Inspection Microscope Nikon Eclipse

|

NanoCalc ReflectometerModel: xxxxx'

descriptionxxxxxxx

Users in Charge: Leader: xxxx

|